TECHNICAL INFORMATION

DEVELOPMENT DESIGN

TECHNICAL INFORMATION

DEVELOPMENT DESIGN

Intergrated System

Development and Design

Intergrated System

Production System

Intergrated System

Quality Assurance

The technological capabilities, know-how, and expertise cultivated since its founding has allowed Kokusan Parts Industry to realize high-performance product development.

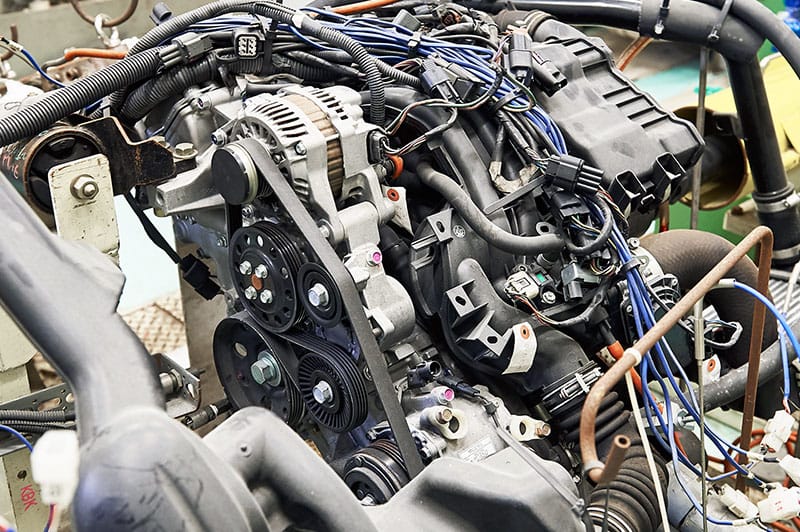

Through coordination with manufacturers from the engine development stage, Kokusan Parts Industry is dedicated to development and design proposals and support that meets the needs of our customers. In this way, the structure and materials of our gaskets are deeply connected to the specified quality and performance of the engine, a fact that in itself exemplifies the level of trust manufacturers have in our products. Our Research and Development Center is constantly analyzing and perfecting not only cylinder head gaskets but also various other gaskets, heat insulators, and other components that play a large role in engine development. Utilizing proprietary technology cultivated over the years, Kokusan Parts Industry strives every day to create high-quality, high-performance products.

Dev & Design

Utilizing a variety of analyses and expertise accumulated throughout the company’s history, Kokusan Parts Industry designs its products to provide performance beyond the expectations of customers.

Our thorough communication with customers and the database of Kokusan Parts Industry allows us to design products quickly.

Dev & Design

Preliminary verification of a product design includes structural, thermal, fluid, and vibration analyses to predict functionality, and molding analysis to predict processing characteristics.

Kokusan Parts Industry strives to find ways to increase the accuracy of prediction analyses in order to shorten development periods and reduce development costs. This dedication has also earned a high degree of trust and praise from our customers.

Dev & Design

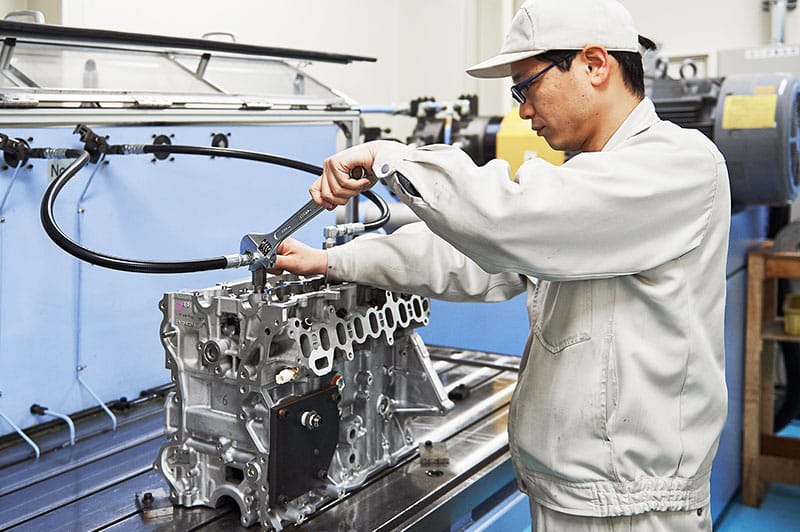

Kokusan Parts Industry manufactures prototypes based on product design blueprints. In addition to using high-precision 2D and 3D lasers for prototyping, our engineers will utilize skills developed from extensive experience to create handmade prototypes as necessary.

Dev & Design

Molds made in-house are the product of our outstanding engineers and are designed to meet the specific needs of the customer. Kokusan Parts Industry also manufactures mass-production molds using various processing machines as part of our efficient design and production services.

Dev & Design

In order to ensure reliability of our products, Kokusan Parts Industry evaluates the durability of metal by testing products for fatigue using a large hydraulic testing machine.

Dev & Design

Kokusan Parts Industry sealing parts such as gaskets undergo evaluations based on the most stringent conditions, particularly important sealability tests.

Dev & Design

Kokusan Parts Industry evaluates the performance of its products when vibration is applied using a vibration testing machine. This machine assumes the level of vibration of an actual product in order to verify the product’s durability.

Dev & Design

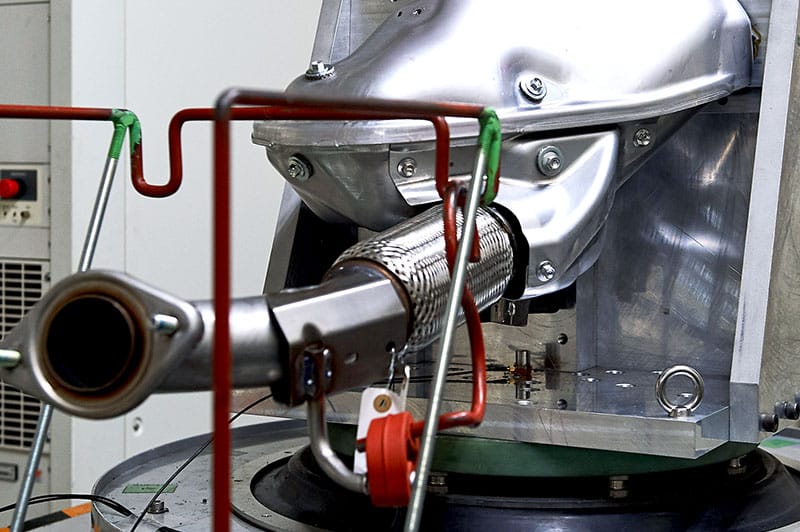

Kokusan Parts Industry evaluates performance by installing and running the products on an engine (24-hour operation). This allows us to test under specific conditions in order to satisfy the various requirements set by manufacturers.

Dev & Design

| Absorption capacity | 130 kw, 150 kw, 220 kw |

|---|---|

| Permissible torque | 350 Nm, 455 Nm, 700 Nm |

| Permissible rotation speed | 7,500 to 10,000 rpm |

| Operation pattern | Full load, high fluid temp, high oil temp, cold, sub-zero endurance (-35°C), etc. |

Dev & Design

| Evaluation details | Durability performance evaluation by applying hydraulic pressure equivalent to combustion pressure to bore portions |

|---|---|

| Setting range of oil pressure load | 0 to 3 MPa (min.)0 to 30 MPa (max.) |

| Test waveform | SIN waveform (0.0001 to 10 Hz) |

Dev & Design

| Evaluation details | Effectiveness evaluation of gaskets in coolant lines by intermittently applying hot and cold fluid |

|---|---|

| Coolant temperature | -20 to +90°C |

Dev & Design

Universal Material Testing Machine, Fatigue Testing Machine, Cold Thermal Shock Testing Machine, Constant Temp/Humidity Chamber