Technical Information

Over the years, Kokusan Parts Industry has developed integrated systems—from development and design to production and quality assurance—to ensure we meet our customers’ needs quickly and satisfactorily.

In addition to our individual products, we actively pursue in-house design, development, and production of molds and production equipment. These pursuits have contributed greatly to improved precision and product quality, not to mention allowing for the creation of an ideal production environment in terms of process control, quality control, and cost.

Interdepartmental cooperation, including between the development and production divisions, is deep-seated. This mutual cooperation allows us to demonstrate our advanced technical capabilities, such as in trial productions for next-generation engines, earning high praise from our customers.

Integrated Systems for Increased Reliability and Assurance

-

1

Integrated System

Development and Design

-

2

Integrated System

Production System

-

3

Integrated System

Quality Assurance

-

1

Integrated System

Development and Design

Kokusan Parts Industry is dedicated to developing high-performance engines through close collaborative development with manufactures and through in-house designs, prototyping, and experimentation.

-

2

Integrated System

Production System

To further its pursuit of more efficient and stable manufacturing, Kokusan Parts Industry employs a variety of state-of-the-art equipment and skilled operating engineers.

-

3

Integrated System

Quality Assurance

Through a vast wealth of knowledge and expertise, Kokusan Parts Industry is able to provide customers with inspection and testing to ensure products are both stable and high-quality.

Pioneering Development and Technological Advancements

SPCCI Cylinder Head Gaskets

Kokusan Parts Industry has developed and mass-produced head gaskets for spark-controlled compression ignition (SPCCI) systems used in Mazda SKYACTIV-X engines. These revolutionary engines boast world-leading performance in both compression ratio and injection pressure. Even with no previous experience developing head gaskets for these engines, Kokusan Parts Industry successfully developed a completely new gasket in cooperation with the engine manufacturer to satisfy the strict requirements imposed by the new combustion method which is different from the conventional gasoline engine.

Through microscopic analysis and evaluation using an electron microscope, the newly developed products significantly improve environmental performance.

The experience and insight gained will also help shape the development of next-generation components in future projects.

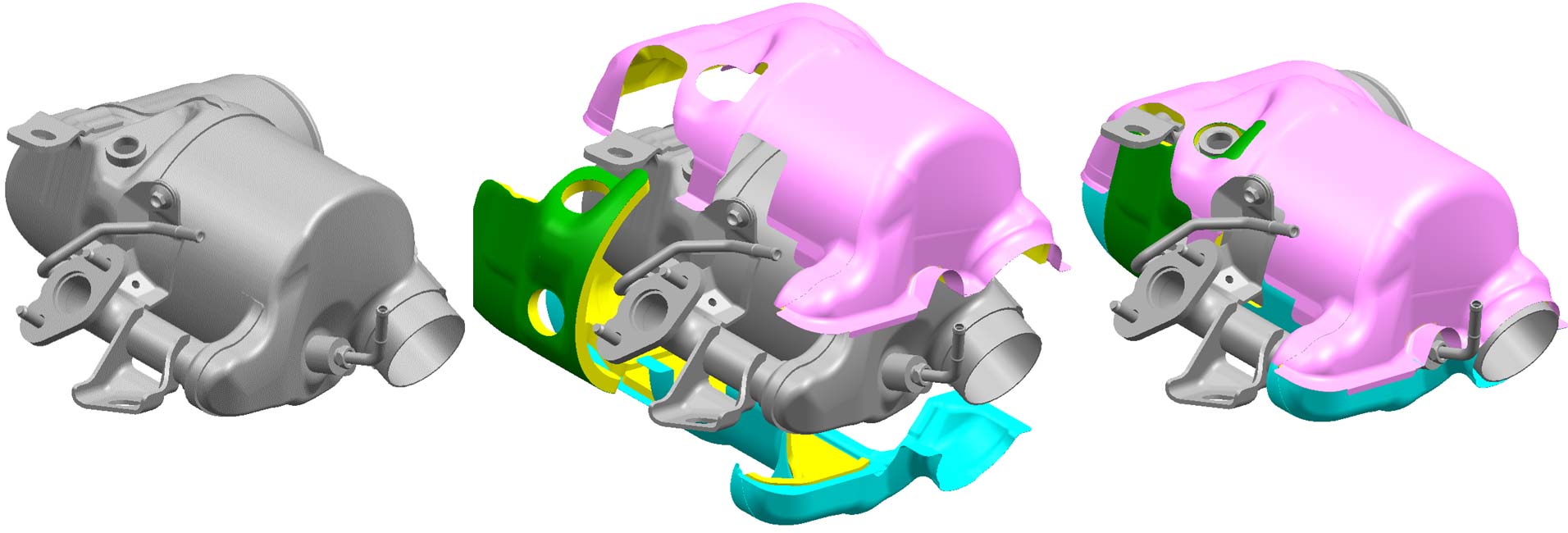

Direct Shield Heat Insulators

Made of a thin stainless steel sheet with a high heat-resistant insulator on the inside, this high-performance heat insulator covers the catalytic converter case in an automobile engine. Using computer-aided engineering to balance material properties and press conditions, Kokusan Parts Industry successfully developed and mass-produced presses for catalytic converter cases with complicated shapes. These efforts were recognized at the 2020 Kyoto Small and Medium Enterprises Technology Awards, earning Kokusan Parts Industry the Outstanding Technology Award.

Catalytic converter case

Assembly

Finished assembly